What We Do

We enhance the value of your investment. We instill confidence in your project. We make your job easier.

We develop and help deliver facades and enclosures that reflect your vision and stand the test of time.

A building is known by its address and its facade. We are honored to have collaborated on these projects.

Commercial

Academic

Multi Family

Entertainment and Hospitality

Solutions, Knowledge And Training

Providing information and knowledge that promotes informed decision making

We work with our clients to help them understand the principles that influence building envelope performance, the strengths and weaknesses of concepts and materials, and the details and construction methodologies that provide the greatest benefit.

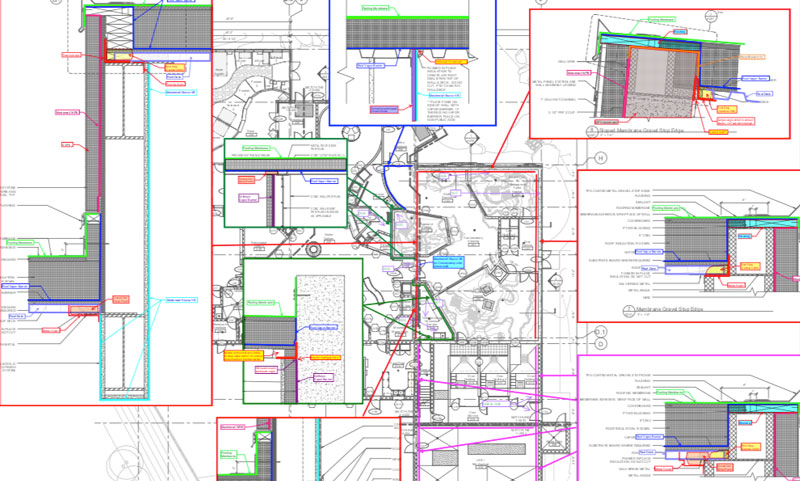

Building Enclosure Commissioning (BECx)

The concept of enclosure commissioning is not new. Its roots are in the high-rise custom curtainwall industry where every project is a new design with specific performance criteria, construction challenges, and validation requirements. Its benefits are now being applied to all enclosure systems and facade types to enhance as-built performance.

Enclosure commissioning is associated with, but not limited to, achieving high-level LEED certification. It encourages advancements in product sustainability, material technology, and performance standards. It promotes accountability during construction and practical ownership for quality assurance and sustainability.

We embrace building enclosure commissioning (BECx) in all the project phases from pre-design through occupancy. Our time-tested quality assurance procedures meet the intent of ASHRAE and the NIBS for building enclosure commissioning. Whether formally or informally implemented, commissioning services will identify and mitigate potential issues early and provide a project that achieves a higher standard of workmanship and sustained performance over time.

Research and Training

We are continually evaluating and testing cutting-edge technology and its potential to improve performance and cost effectiveness. A primary focus is demonstrating to project contractors that these initiatives, and the additional skills and resources required to implement them, are in their best interest.

We have been implementing co-extrusion and pultrusion components, composite FRP claddings, and cold-formed glazing and framing systems as these technologies become available. We continue to develop pre-fabricated, panelized facade systems that rely less on sealants. Our purpose is to ultimately eliminate exposed sealants and the need to replace them.